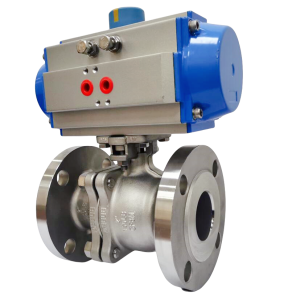

MIWIVAL ball valves are engineered to ensure bubble-tight shutoff and low operating torque.

The ball valves utilize an independent packing gland which can be easily adjusted without removing mounting hardware or operator. The packing gland is contoured to uniformly distribute the load across the packing. The live load packing is self-adjusting due to its Belleville washers allowing it to compensate for environmental changes and wear, ensuring maintenance free operation and long cycle life.

All resilient seat materials ensure bi-directional, bubble tight sealing and feature relief slots on the seat outer diameter to relieve pressure past the upstream seat in case of an upset situation such as trapped gas in the valve body as well as positive preloading to ensure low pressure/vacuum sealing capability.

Non-Fire Safe and API 607 Fire Safe Valves:

Ball valves are available as non-fire safe with standard stem seals or fire safe to API 607 with graphite stem seals.