What is Steam Conditioning and Desuperheating?

A desuperheater injects a controlled, predetermined amount of water into a steam flow to lower the temperature of the steam. To achieve this efficiently, the desuperheater must be designed and selected correctly for the application. Although it can appear simplistic in design, the desuperheater must integrate with a wide variety of complex thermal and flow dynamic variables to be effective. Steam conditioning valves control steam pressure and temperature by combining both functions within one integral control unit. These valves address the need for better control of steam conditions brought on by increased energy costs and more rigorous plant operation. Steam conditioning valves also provide better temperature control, improved noise abatement, and require fewer piping and installation restrictions than the equivalent desuperheater.

The simplest type of desuperheater is an unlagged section of pipe, where heat can be radiated to the environment. However, apart from the obvious risk of injury to personnel from such a hot item of plant, and the expensive energy wastage, this approach does not adjust to compensate for changes in the environmental conditions, steam temperature or steam flowrate.

Several designs of desuperheater are available and it is recommended that the following properties be considered when sizing and selecting a suitable station for a given application:

Water spray type desuperheaters

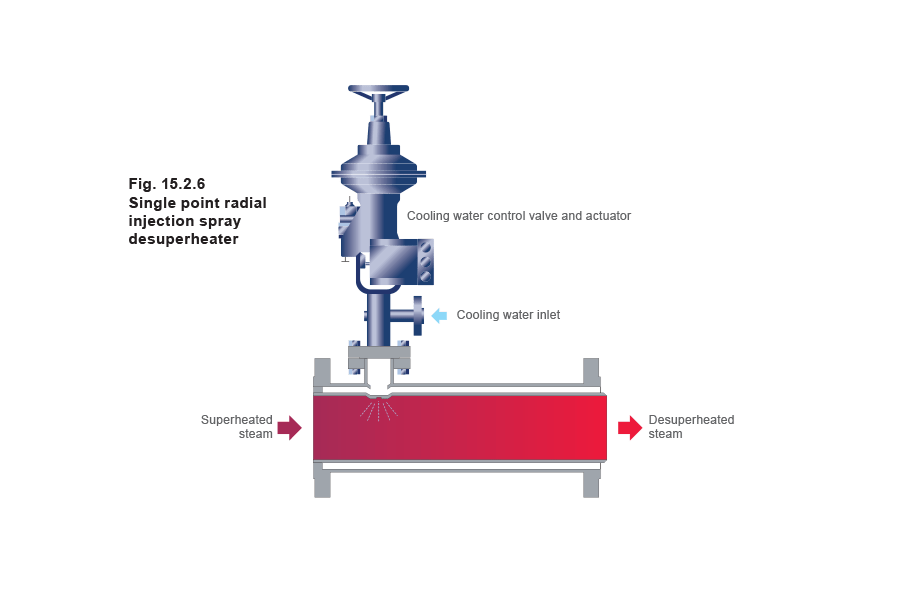

Single point radial injection spray desuperheaters

The simplest method of injecting cooling water is to introduce a nozzle through the pipe wall.

The cooling water particles are sprayed across the flow of the superheated steam. The quantity of cooling water injected is controlled by varying the position of the valve in the centre of the nozzle.

Advantages:

- Simple in operation.

- Cost effective.

- Minimum steam pressure drop.