The discharge valve is mainly used for discharging materials at the bottom of the storage tank, reaction kettle, and other vessels.

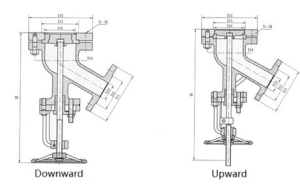

The discharge valve can be divided into upward and downward types. The Upward type is used for discharging the reactor with the agitator discharging valve; the downward type is used for the reaction kettle discharging of the frame-type anchor agitator.

The main differences between upward and downward discharge valve lie in the opening and closing direction of the disc, torque and material discharge method. The disc of the upward discharge valve moves upward, and the force of the medium needs to be overcome when it is opened, so the torque is large when it is opened. The valve disc of the downward discharge valve moves downward, and the direction of movement is the same as the medium force when it is opened, so the torque when it is opened is small.

The common characteristics of the two types are the close distance between the valve seat and the end flange, less material retention, compact structure, and superior sealing performance.