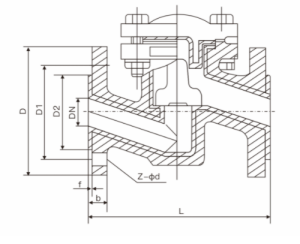

1. Superior corrosion resistance. The mostly used material of the Fluoroethylene lined check valves is PTFE, which has excellent corrosion resistance and can withstand corrosion from various strong acids, alkalis and oxidants, and can even withstand “aqua regia”.

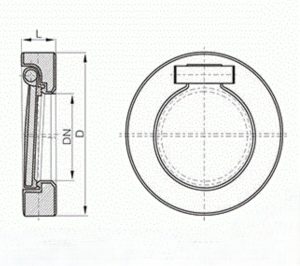

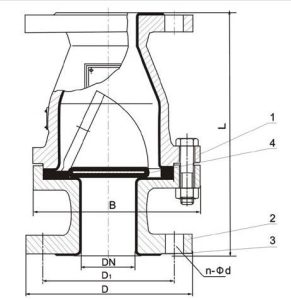

2. Compact size & light weight. Their FTF length and weight is only 1/4~1/8 of the traditional flange check valve.

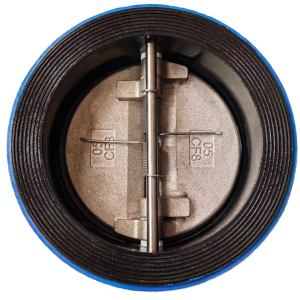

3. Quick opening and closing. It opens and closes quickly and sensitively, and the water hammer pressure is small.

4. Easy installation. It can be used in horizontal or vertical pipelines and is easy to install.

5. Small fluid resistance. The flow channel is unobstructed and the fluid resistance is small.

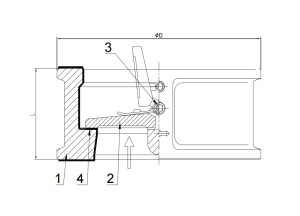

6. Good sealing performance. When the pressure is higher, the force of the fluids pushing the valve disc against the valve seat is greater, and the sealing effect is better under tighter sealing.

7. Short valve stroke. The valve disc stroke is short due to the compact size and the valve closing impact force is small.

8. Long lifespan and easy maintenance. The overall structure is simple and highly reliable, so it’s easy to maintain and can be serviced in the pipe system for long time.

Applications: Water, gas, oil, chemical industry, smelting, energy, shipbuilding, electricity, petroleum, water treatment, construction and other industries.