Understanding Flanged Ball Valves: Key Features and Applications

The Flanged Ball Valve Basics

What is a Flanged Ball Valve?

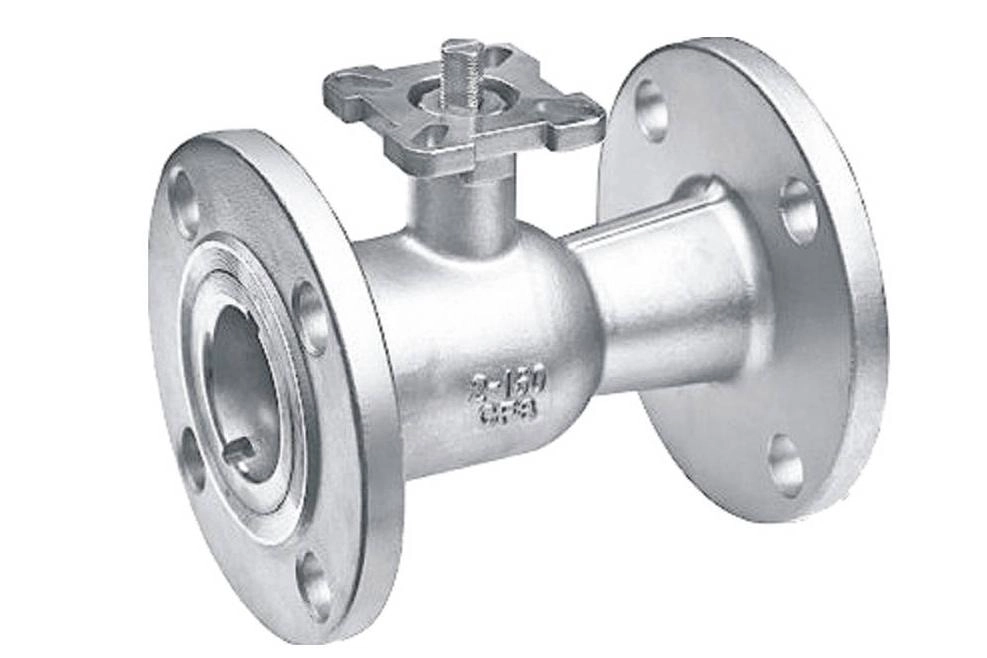

Flanged ball valve is a type of valve that employs a rounded ball to manage the movement of liquids or gases within a system. The spherical ball features an opening that permits the fluid to pass through when it lines up with the pipeline. By turning the ball 90 degrees using either the valve handle or actuator mechanism in place the flow is obstructed effectively. This design guarantees regulation and rapid closure capabilities. Their designation as flanged ball valves originates, from their extremities that enable secure bolting onto pipelines.

Basic Structure and Components of a Flanged Ball Valve

A flanged ball valve usually includes important parts, in its design.

- Valve Body: The main housing that contains all internal components.

- Ball: A spherical component with a hole (bore) through its center.

- Stem: Connects the ball to the actuator or handle, enabling rotation.

- Seats: Provide sealing between the ball and valve body to prevent leakage.

- Flanges: Located at both ends of the valve body for secure attachment to pipelines.

- Handle or Actuator: Used to manually or automatically rotate the stem and ball.

This mix of parts guarantees lasting quality and effective operation without any leaks, for a wide range of uses.

Key Differences Between Flanged Ball Valves and Other Valve Types

Flanged ball valves have characteristics that make them stand out from any other type of valve.

Design Simplicity: In contrast to gate or globe valves, flanged ball valves possess fewer moving parts and therefore experience less wear and tear.

Fast Operation: A simple quarter-turn operation allows fast opening and closing.

Leak Prevention: The close fit provided by seats minimizes leakage compared to other forms of valves.

Flow Efficiency: Low pressure drop and unobstructed flow is offered by the full-bore design.

Flanged ball valves are the best for use because they are effective and trusted and can therefore be used in various applications, in industry.

Key Features of Flanged Ball Valves

Durability and Reliability in Industrial Applications

Flanged ball valves are recognized for their build quality that makes them perfect for harsh industrial conditions. They are resistant to pressures and temperatures well and can perform efficiently in the long run. Furthermore, the fact that they resist corrosion extends their durability when coming into contact, with harsh chemicals.

High Flow Efficiency and Minimal Pressure Drop

A notable characteristic of flanged ball valves is their flow efficiency since they have a full bore through which fluid can flow with minimal hindrance which helps in minimizing pressure drop, across the valve; this feature assumes particular significance in processes where constant flow rates are crucial.

Ease of Maintenance and Long Service Life

Flanged ball valves are made for upkeep purposes with their easily detachable parts, for quick replacement without having to take out the whole valve from the pipeline—a feature that cuts down downtime and maintenance expenses significantly Additionally their strong materials add to their longevity of use.

Compatibility with Different Materials and Media

Flanged ball valves are manufactured with numerous different materials, such as stainless steel, carbon steel, brass, or PVC. With their versatility, they can be used to accommodate various types of media, such as water, oil, gas, chemicals, and slurries. Because of their versatility, they are an option product across various industries such as oil & gas, chemical processing, water treatment, and power generation.

Specialized Configurations

3-Piece Flanged Ball Valve

The design of a 3 piece flanged ball valve provides added flexibility for maintenance needs comprising three parts; two end caps equipped with flanges and a central body housing the ball mechanism enabling users to detach only the central part, for servicing while keeping the end caps connected to the pipeline.

Double-Piston Effect Anti-Blowout Stems

Certain tech flanged ball valves are equipped with double piston effect anti-blowout stems to enhance safety measures. This innovative design ensures that the stem remains securely in place during high-pressure situations thanks, to the collaboration of dual seals that effectively contain pressure within the valve body.

Control Ball Valves

Specialized control ball valves are crafted for adjusting flow rates instead of just turning flow off or turning it back into operation mode like regular valves do. They frequently integrate V port balls or make bore shapes to enable precise control, over the movement of fluids in a system.

Cavity Filler

Configurations for filling cavities are employed in scenarios where it’s crucial to avoid contamination or the accumulation of residues. These setups address any spaces around the ball located inside the valve body by employing elastomers such as polytetrafluoroethylene (PTFE) guaranteeing the function of systems in sectors, like food manufacturing or pharmaceutical industries.

Piggable/Full Bore Designs

In industries such as oil and gas, it’s crucial to have flanged ball valves, with full bore designs that enable pipeline cleaning tools, known as pigs to move through smoothly without any blockages impacting operational efficiency.

Professionals can choose customized flanged ball valves that meet their requirements and offer optimal performance advantages in various scenarios by grasping these setups and characteristics.

Common Applications of Flanged Ball Valves

Use in the Oil and Gas Industry

Ball valves with flanges are crucial in the oil and gas sector as they are used to regulate the movement of oil, natural gas, and other hydrocarbons. Their strong build and capacity to manage high-pressure conditions make them capable of being compatible with operations along midstream and downstream operations. The valves are commonly used, in pipelines, refineries, and storage terminals to facilitate the transport and processing of petroleum products. Flanged ball valves’ effective sealing ability plays a role, in reducing the risk of leaks and upholding safety regulations to safeguard the environment within this industry sector.

Role in Chemical Processing Systems

In chemical process systems, flanged ball valves are essential in controlling the flow of chemicals like corrosive and dangerous chemicals. The valves can resist chemical environments since they can function with various materials like stainless steel or PTFE-lined parts. Their versatility makes them remain efficient and reliable in challenging conditions. Moreover, the accurate regulation provided by these valves facilitates measurement and blending procedures that are essential, for manufacturing top-notch chemical goods.

Application in Water Treatment Facilities

Flanged ball valves are used in water treatment plants to control the flow of water through water filtering and distribution of water since they can withstand wear caused by use under moist conditions. Valves are prized due to their resilient nature and ability against deterioration through the constant process of function under watery conditions. The full bore style of flanged ball valves helps minimize pressure drop and improve the effectiveness of water treatment systems. Moreover, the easy maintenance they offer reduces downtime making them a budget-friendly choice, for water management endeavors.

Importance in Power Generation Plants

Power plants use flanged ball valves to control the flow of steam and cooling water for generating energy efficiently and safely in power generation operations Strategies are under development to improve the stability and efficiency of power generation systems through the use of reliable flanged ball valves that can withstand extreme temperatures and pressures These valves play a crucial role in ensuring quick shut off for emergency situations or maintenance tasks enhancing overall safety measures, within power plants.

Industry-Leading Flanged Ball Valve from Miwival

Superior Quality Materials for Enhanced Performance

Flanged ball valves from Miwival are manufactured using superior-quality materials that ensure enhanced performance across various applications. Using corrosion-resistant material such as stainless steel or duplex steel, these valves are highly resilient even in most rugged industrial environments. Sealing technology such as PTFE or graphite also gives them increased leak-tightness as well as longer service life.

Precision Engineering for Reliable Operation

Miwival’s flanged ball valves are meticulously crafted with a focus on precision engineering at their core. The valves go through testing to meet global quality and safety standards. Additional safety features like blowout stem and fire-safe designs offer extra protection against potential hazards. The precise machining of components ensures operation and longevity reducing wear and tear for reliable performance, for long periods of time.

Miwival offers top-notch products offering a synergy of the most modern design, coupled with high-quality materials to fulfill the stringent demands of contemporary industries while ensuring excellent performance and reliability. If you need any products from Miwival, you can contact us anytime.

FAQ

Q: What is a flanged ball valve?

The flanged ball valve belongs to the category of quarter-turn valves featuring ends, designed for seamless integration, with pipelines utilizing a rotating ball containing a central hole to regulate the flow of fluids.

Q: What are the advantages of a flanged ball valve?

A: There are advantages as below:

Strong and secure connection to pipelines

Easy installation and removal

Excellent sealing performance

Ideal for use in situations, with levels of pressure and temperature.