How Butterfly Valves Regulate Flow in Industrial Applications

Understanding Butterfly Valves

What Are Butterfly Valves?

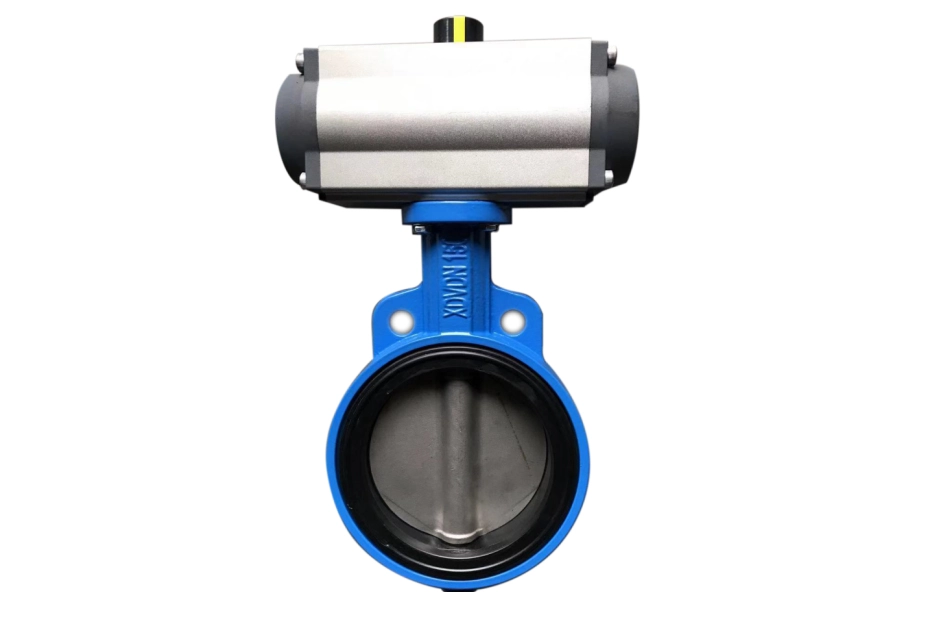

Butterfly valves are often utilized in settings to manage fluid flow by regulating or blocking it using a rotating disc within a pipe system known for being light, in weight, and cost-effective when compared to alternative valve options.

Key Components of Butterfly Valves

Valve Body and Disc

The valve body acts as the shell containing all the internal parts. The disc located within the body is crucial for controlling the flow. It can. Stop the fluid from passing through the valve when turned in a certain way.

Stem and Seat

The stem links the actuator (either an automatic device or a hand lever) and the disc so that the disc can rotate easily. The seat acts as a seal between the disc and the valve body so that there are no leaks when the valve is screwed shut. These parts are usually constructed from materials such as stainless steel or rubber to adapt to different operating conditions.

Types of Butterfly Valves

Concentric Butterfly Valves

Butterfly valves with a design have a stem and disc placed at the center for optimal contact with the seat to create a reliable seal suitable for low-pressure uses.

Double-Eccentric Butterfly Valves

Offset butterfly valves feature a stem and disc arrangement with an offset design that minimizes friction between the disc and seat while in use. Ideal for systems operating at higher pressures.

Triple-Eccentric (Triple-Offset) Butterfly Valves

Eccentric butterfly valves incorporate an extra offset in their structure to reduce the interaction between the disc and seat significantly This setup boosts longevity and enables their application in environments with extreme temperatures and pressures.

The Working Mechanism of Butterfly Valves

How Butterfly Valves Control Fluid Flow

Butterfly valves regulate the flow of liquids by adjusting the placement of their disc; when fully open, the disc lines up parallel to the flow path to enable maximum fluid movement; however when closed it pivots perpendicularly to completely halt the flow.

The Role of the Disc in Flow Regulation

The disc plays a role in managing the flow in butterfly valves by altering its position in relation to the fluid flow direction to allow operators to have precise control over the flow rates.

Quarter-Turn Operation Explained

Butterfly valves work by turning a quarter of the way around the idea; rotating the actuator by 90 degrees shifts the disc between open and fully closed positions or vice versa making them efficient and user friendly in different scenarios.

Applications of Butterfly Valves in Industrial Settings

Common Industries Utilizing Butterfly Valves

Oil and Gas Industry

In the oil and gas industry butterfly valves are commonly used to isolate pipelines and control flow. Their effectiveness in managing pressures and corrosive materials makes them a popular choice for such applications.

Water Treatment Facilities

Water treatment facilities heavily rely on butterfly valves to regulate the flow of water during the purification procedures due to their performance and minimal maintenance needs which make them a perfect fit for this purpose.

Chemical Processing Plants

The chemical sector depends on butterfly valves to manage chemicals in different temperature settings effectively and safely due to their durable design ensuring optimal performance in challenging conditions.

Advantages of Using Butterfly Valves in Industrial Systems

In systems and installations with limited space requirements like Butterfly valves can be beneficial due to their lightweight nature and low cost of installation compared to traditional alternatives while also being easy to set up and requiring minimal upkeep for reliable performance in various operating conditions.

Maintenance and Longevity of Butterfly Valves

Regular Inspection Protocols

It’s important to check butterfly valves to make sure they are working well and will last long term. During an inspection; Look at the valve body to ensure there are no cracks or defects that could weaken it. Check the disc for corrosion or any buildup that could affect how it controls flow. Examine the stem and seat for any wear or damage. This kind of examination helps keep the valves in good shape for a longer time. The base needs to be checked for alignment and smooth functionality to avoid any issues with efficiency in operations. Moreover it is important to examine the chair for signs of wear or tears to uphold a seal and prevent any potential leaks.

Maintaining the operation of moving components is essential for upkeep purposes too! Using the lubricants on the stem and actuator helps reduce wear caused by friction and ensures everything runs seamlessly. Don’t forget to check that the actuator works well during inspections. Whether it’s operated manually or automated!

Common Issues and Troubleshooting Tips

During the lifespan of butterfly valves, they may face a number of issues that are often encountered in their operation over time. One common issue that arises is leakage occurring around the valve seat, which is usually caused by wear and tear or damage to the seat material itself. To effectively address this problem replacing the seat with a material has proven to be a successful solution.

There’s another issue that often crops having trouble with the valve’s operation can stem from a misaligned stem or debris accumulation on the disc itself. Restoring its function involves cleaning the disc and realigning the stem as needed. Sometimes if it takes a lot of force to work the valve smoothly points to problems like lubrication or damage to its internal parts.

Dealing with corrosion poses a hurdle in scenarios where harsh chemicals or moisture are prevalent! Opt for butterfly valves constructed from corrosion-resistant materials like steel to fight this problem effectively! For any issues arising and requiring troubleshooting measures in place, it is recommended that you utilize the manufacturer’s guidelines specific to the type of butterfly valve you are using.

Extending the Lifespan Through Proper Care

Caring for butterfly valves and performing maintenance can actually prolong their functionality and lifespan. It is necessary to have a maintenance plan to detect any issues at an early stage before they turn into enormous headaches. Operators should be cautious while operating the valves within the specified pressure and temperature limits to prevent any strain or damage to the components.

Regular maintenance of the valve keeps sediments or corrosive materials from forming which would affect its operation in the long term. During operation under certain conditions where there is the application of a protective coating on the disc and seat minimizes wear and extends their lifespan.

Providing training for staff on the correct handling and operation methods also plays a significant role in prolonging the lifespan of valves as it helps to reduce undue stress on components by ensuring operators are well-versed in the proper use of actuators.

Miwival’s High-Quality Butterfly Valves

Features of Miwival’s Advanced Butterfly Valve Designs

At Miwival, we provide butterfly valve designs that are customized for a wide range of industrial uses ensuring top-notch performance in different operating environments.

The butterfly valves made by Miwival are built strong with top-notch materials like steel and advanced polymers to withstand tough conditions effectively. They stand out for their design that includes triple eccentric setups to lessen friction between the disk and seat which helps in durability and better sealing performance. These Valve products are perfect for systems that operate under pressure and temperature conditions where a dependable performance is crucial.

The valves come with actuators that provide accurate control of fluid flow. Whether operated manually or automatically these actuators ensure quarter-turn operation with little effort. Furthermore, Miwival features cutting-edge sealing technologies that prevent leaks in challenging conditions.

Quality is a priority for Miwival that goes beyond just the design aspects. Their butterfly valves go through thorough testing to meet the standards set by the industry. It guarantees performance in various settings like oil and gas pipelines, waste water treatment facilities, and chemical processing plants. If you have any needs, you can contact us anytime!

FAQ

Q: What standards apply to butterfly valves?

A: ISO 10631:2021 specifies requirements for metallic butterfly valves, covering design, materials, testing, and installation. Compliance ensures performance under pressure, temperature, and corrosion conditions. Manufacturers often follow these standards for industrial-grade valves.

Q: Why do larger butterfly valves (≥8″) experience increased torque?

A: In liquids, closing larger butterfly valves (>8″) generates higher dynamic torque due to fluid resistance and disc movement. This requires robust actuators to ensure smooth operation.