Eccentric Rotary Plug Control valve is a type of valve converged the best control features of a conventional globe valve with a rotary action to produce a valve capable of replacing at least 80% of the control valves in use at that time.

Eccentric plug rotary control valves control erosive, coking, and other hard-to-handle fluids, providing either throttling or on/off operation. The flanged valves feature streamlined flow passages and rugged, metal trim components for dependable service in slurry applications. These valves are used in mining, petroleum refining, power, and pulp and paper industries.

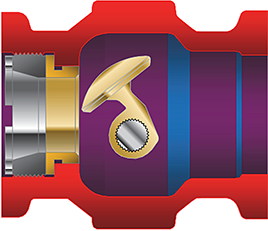

The heart of the valve is its eccentric plug. The eccentrically rotating, double offset plug into and out of the seat. This camming action eliminates friction throughout its rotation since the plug moves away from the seat as it opens, unlike other rotary valve types. This ensures precise control at all openings.

The plug is offset such that the trailing edge of the plug face will contact the seat ring first when closing. Additional plug rotation causes the plug arms to flex slightly, moving the plug face into full contact with the seat. This flexing action ensures tight long-term seating with smooth seating/unseating action.

Linear Flow Characteristic with Higher Turndown

Miwival’s linear flow characteristic provides a slight modification as the plug approaches the seat. As the plug cams into the seat, the rate of change in flow is reduced gradually until the plug contacts the seat. This provides a Cv ratio of 100:1 for stable operation over a wider range in flow. Most traditional globe style control valves offer 50:1 maximum.

Applications

- Refining

- Petrochemicals

- Chemicals

- Natural gas

- Fertilizers

- Power