Total Quality Control- ISO 9001 certified

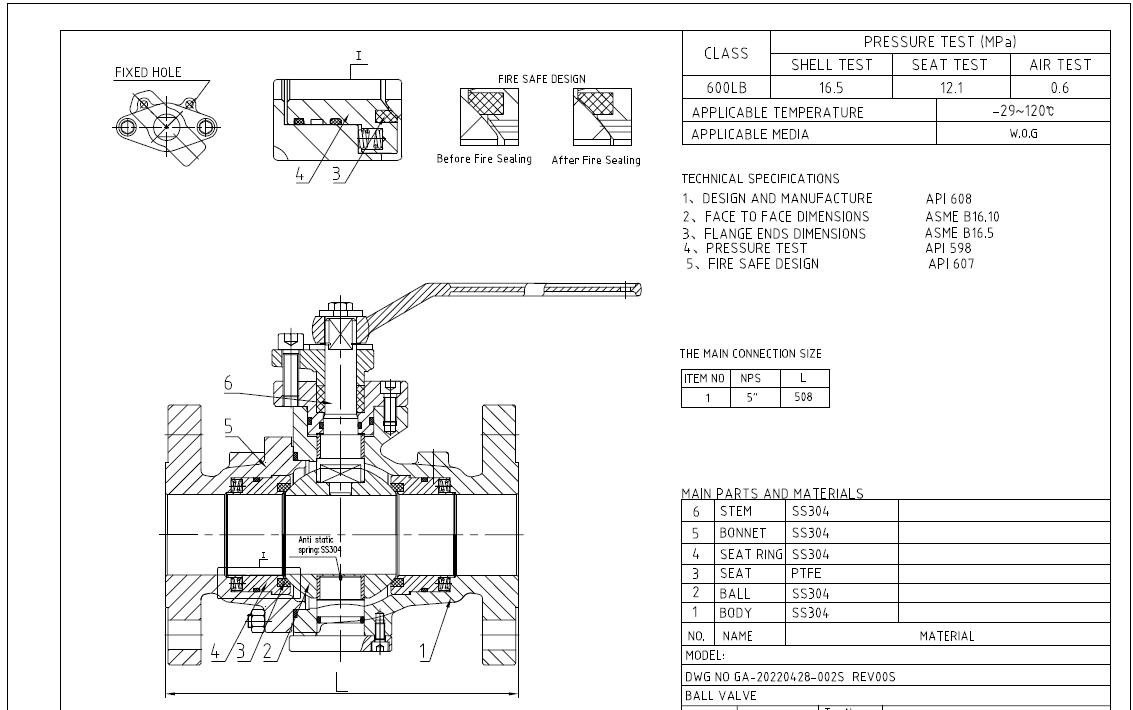

From Raw material to Finished valves 1. Visual Inspection on the casting & forging 2. Dimension Inspection on casting & forging 3. Chemical Analysis & PMI inspection 4. Mechanical Examination 5. Quality inspection in machining & assembling 6. NDT testing 7. Pressure Testing 8. Painting inspection 9. Final Inspection before the shipment 10. Packing inspection 11. ISO 10204: 3.1/3.2 material certification

Material Verification and Traceability

Miwival 's calibrated equipment in accordance with international requirements

Positive Material Identification

Trained operators using certified equipment perform in-house PMI testing to verify material traceability reports

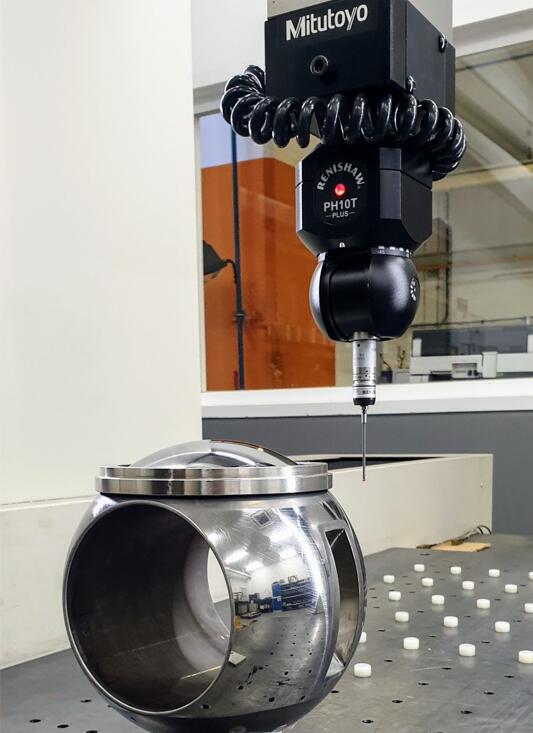

Coordinate Measurement

Touch probing methodology throughout the engineering and manufacturing process verifies physical characteristics.

Valve Sizing for Control Valve

Valve sizing is critical for the control valve. Right vavle for right application

Final packing

Final packing is the last procedure to make sure that the valves will be delivered to site safely.

Documentation

MIWIVAL has a unquie doc no and revision no for each documents to ensure the traceability including 3.1/3.2 certificates, drawings and data sheets etc