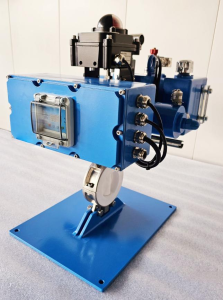

Fluoroethylene Lined Butterfly Valves

Features & Benefits

1. Strong corrosion resistance. The valve body of the fluoroethylene-lined butterfly valve is lined with fluoroethylene plastic material (usually PTFE), which can effectively resist the erosion of corrosive media such as acids, alkalis, and salts, and is suitable for a variety of corrosive media environments.

2. Good sealing performance. The soft sealing structure is adopted, and the fluoroethylene plastic material is used for sealing between the valve seat and the valve disc, which has good sealing performance and can effectively prevent medium leakage. It is suitable for special working conditions such as high temperature and low temperature.

3. Space saving. The fluoroethylene-lined butterfly valve is small in size, light in weight, simple and compact in structure, and can save installation space.

4. Flexible and convenient operation. The lightweight wheel design is adopted, which is flexible and convenient to operate and is suitable for occasions that require frequent operation.

5. Small flow resistance. The valve disc adopts a flat plate structure, and the flow resistance when the fluid passes through is small, which can effectively reduce the system pressure loss.

6. Low cost. The manufacturing cost is low, the maintenance is convenient, and the long-term use cost is relatively low.

7. Novel and reasonable design. Unique design, light weight, fast opening and closing, small operating torque, convenient and labor-saving operation.

8. Reliable sealing performance. The seal can be replaced, the sealing performance is reliable, and can meet the zero leakage.

9. Wide range of applications. Widely used in the transportation of liquids and gases in various industrial pipelines, especially in highly corrosive media environments.