Common Valve Types and Applicable Media

1. Valve classification

(1) According to the operation mode: linear motion valves and rotary motion valves.

① Linear motion valves use a closure member that moves in a straight line to start, stop, or throttle the flow. The closure device could be a disc, slat or flexible material, like a diaphragm. Linear motion valves tend to be slower in operation, but they have a higher level of accuracy and stability in the position of the closure member. The closure device can be used to: Move a disc, or plug into or against an orifice; Slide a slat, cylindrical, or spherical surface across an orifice; Move a flexible material into the flow passage. The most common example of linear motion valves includes gate valves, globe valves, fixed cone valves, needle valves, and pinch valves.

② Rotary motion valves rotate a disc or ellipse about an angular or circular shaft extending across the diameter of an orifice. They are also known as quarter turn valves. Quarter turn valves will be in their fully open or fully closed state (0°) after a 90° turn of the stem. Their operation is much quicker than linear motion valves.The most common examples of rotary motion valves include ball valves, butterfly valves, plug valves, and spherical valves.

(2) According to function: shut-off valve, check valve, safety valve, regulating valve and diverter valve.

① Cut-off valve: Cut-off valve is also called closed-circuit valve (on-off valve). Its function is to connect or cut off the medium in the pipeline. Cut-off valves include gate valves, globe valves, plug valves, ball valves, butterfly valves, etc.

② Check valve: Check valve is also called one-way valve or non-return valve. Its function is to prevent the medium in the pipeline from flowing back.The bottom valve of the water pump suction valve also belongs to the check valve category.

③ Safety valve:The function of safety valves is to prevent the medium pressure in the pipeline or device from exceeding the specified value, thereby achieving the purpose of safety protection.

④ Control valve:Control valves include control valves, throttle valves and pressure reducing valves, whose function is to adjust the pressure, flow and other parameters of the medium.

⑤ Diverter valve: Diverter valves include various distribution valves (three-way ball valves) and steam traps, etc. Their function is to distribute, separate or mix the media in the pipeline.

(3) According to the design structure: ball valve, butterfly valve, gate valve, globe valve, check valve, plug valve, diaphragm valve, safety valve, pressure reducing valve, needle valve, pinch valve, etc.

|

Type |

Description |

Advantage |

Disadvantage |

|

Ball valves |

Rotational motion valves used to start, stop or throttle flow. The valve uses a ball shaped disk with a hole in it. When the valve is opened the hole of disk is turned in-line with the direction of the flow. When the valve is shut, the ball is rotated so that the hole is perpendicular to flow direction. |

Less expensive |

Relatively poor for throttling |

|

Low maintenance costs |

Throttling leads to seat erosion |

||

|

Low torque |

|

||

|

Quick action on/off |

|

||

|

Compact |

|

||

|

No lubrication |

|

||

|

Tight sealing |

|

||

|

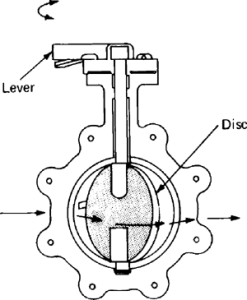

Butterfly valves |

Rotary motion valves that can be used in on-off and throttling systems. They are quick and easy to operate. The flow control element is on either a vertical or horizontal axis and is opened when the handle is rotated 90 degrees and closed when the valve is turned an additional 90 degrees. |

On/off as well as throttle/regulate |

|

|

Easily/quickly operated |

|

||

|

Good for large flow/low pressure applications due to saving in weight/size/cost |

|

||

|

Good for slurries/suspended solids. |

|

||

|

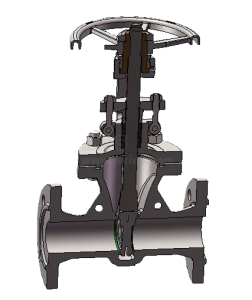

Gate valves |

Linear motion valves used to start and stop flow. The valve is completely opened when the disk is removed from the flow stream. Classification of gate valves is made by the type of disk used: solid wedge, flexible wedge, split wedge, or parallel disk. |

No resistance to flow when open |

Flow changes nonlinearly with stem travel |

|

Little pressure drop |

Vibration/cavitation when partially open |

||

|

Good sealing when closed |

Subject to wear |

||

|

Little/no leakage |

Repair work is difficult |

||

|

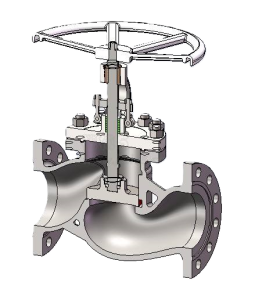

Globe valves |

Linear motion valves used to start, stop and regulate flow. The disk moves perpendicular to the seat to open or close the flow so the annular space between the disk and seat ring gradually changes. There are three body designs for globe valves: Z-body, Y-body, and angle and three designs for the disk: ball disk, composition disk, and plug disk. |

Throttling and regulating flow |

High head loss due to flow direction changes |

|

Less seat leakage than Gate Valve |

Dynamics can create pulsation and damage trim/packing/actuators |

||

|

|

Noisy in high pressure applications |

||

|

|

Valves can be very heavy/large in size for a given application |

||

|

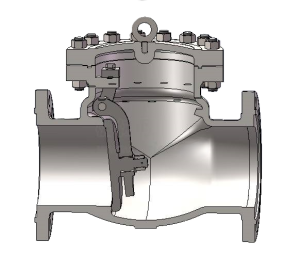

Check valves |

Check valves are used in systems employing gate valves because they prevent the reversal of flow in the piping system and there is a low pressure drop across the valve. The pressure of the fluid through the system opens the system, while the weight of the check mechanism will close the valve if the flow is reversed. |

Prevents reverse flow |

|

|

Plug valves |

Rotation motion valves used to stop and start fluid flow. The disk is a solid tapered or cylindrical plug with a bored passage at the right angle to the longitudinal axis of the plug. When open, the plug lines up with the inlet and outlet port of the valve body. The plugs are either round or cylindrical with a taper. Plug valves are easy to adapt. |

Rotational motion |

Typically NOT for throttling |

|

Suitable for multi-port designs |

|

||

|

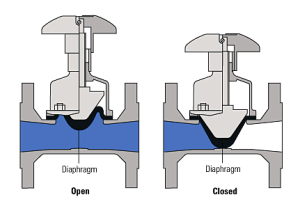

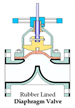

Diaphragm valves |

Linear motion valves that are used to start, regulate, and stop fluid flow. The disk is flexible and seals with the seat in an open area at the top of the valve body. |

Well-suited for difficult environments (corrosive chemicals, slurries, radioactive fluids) |

|

|

Ability to throttle |

|

||

|

Relief and safety valves |

A relief valve opens slowly as the pressure increases about the set-point and only opens as necessary. A safety valve rapidly opens as the pressure setting is reached and will stay open until the pressure is lower than the actuating pressure set-point. Both valves are used to prevent damage by relieving accidental over- pressurized fluid systems. |

Prevents over-pressurization |

|

|

Relief valves are used for incompressible fluids such as water or oil |

|

||

|

Safety valves are used for compressible fluids such as steam. |

|

||

|

Reducing Valves |

Automatic valves that reduce supply pressure to a preselected pressure. The supply pressure must remain at least as high as the selected pressure. |

Automatically reduces supply pressure to preselected pressure |

|

|

Needle valves |

Needle valves have a long, tapered, needle-like point that is used to make relatively fine adjustments in the amount of fluid flow. They are sometimes used as component parts for other valves because the needle allows for a gradual change in the size of the fluid flow opening. |

Good for fine adjustment throttling |

|

|

Pinch valves |

The simplest of any valve design. Pinch valves consist of a sleeve molded of rubber or other synthetic material and a pinching mechanism. The pinching mechanism, a bar or gate, is lowered onto the valve body to cut off the flow through the system. |

Relatively inexpensive |

|

|

On/off as well as throttling/regulating |

|

||

|

Good for slurries, solids |

|

||

|

Well-suited for difficult environments |

|

2. Media type and valve applicable media

The system media is a critical consideration when selecting a valve. Media is a term used to describe the material that will be passing through the system. Media plays an important role when selecting the valve body and disc composition as well as the type and speed of the actuator. There is a wide variety of materials that could be used in the valve system; these include:

(1) G: Gas. Including air, compressed air, steam, natural gas, mixed gas, pure gas, acid gas, alkaline gas, corrosive gas, etc.

(2) L: Liquid. Including liquefied petroleum, gasoline (diesel), water (hot or cold water, clean or dirty water, fresh water or salt water), acidic liquid, alkaline liquid, corrosive liquid, etc.

(3) S: Solids. Such as powder, etc.

(4) High viscosity or viscous fluids,or liquids containing solid particles. Including lubricating oil, hydraulic oil, paint, syrup, jam, mud, pulp and so on.

Refer to the following table for the applicable medium conditions of different valve types:

|

Valve Type |

Media |

Valve Function |

Mechanical Motion |

||||||||||||

|

|

Liquid |

Gas |

Solids |

|

|

|

|

|

|||||||

|

|

Neutral |

Corrosive |

Hygienic |

Slurry |

Fibrous Suspension |

Neutral |

Corrosive |

Vacuum |

Abrasive Powder |

Lubricating powder |

On/Off |

Control Valve |

Linear |

Rotary |

Quarter Turn |

|

Ball Valves |

✓ |

✓ |

|

✓ |

|

✓ |

✓ |

✓ |

|

|

✓ |

|

|

✓ |

✓ |

|

Butterfly Valves |

✓ |

✓ |

✓ |

✓ |

|

✓ |

✓ |

✓ |

|

|

✓ |

✓ |

|

✓ |

✓ |

|

Diaphragm Valves |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

|

|

|

✓ |

✓ |

✓ |

|

|

|

Gate/Knife Valves |

✓ |

✓ |

|

✓ |

✓ |

✓ |

|

✓ |

|

✓ |

✓ |

✓ |

✓ |

|

|

|

Globe Valves |

✓ |

✓ |

|

|

|

✓ |

✓ |

✓ |

|

|

✓ |

✓ |

✓ |

|

|

|

Needle Valves |

✓ |

|

|

|

|

✓ |

✓ |

|

|

|

|

✓ |

✓ |

|

|

|

Plug Valves |

✓ |

✓ |

|

|

|

✓ |

✓ |

|

|

|

✓ |

|

|

✓ |

✓ |