How a Bidirectional Knife Gate Valve Enhances Fluid Control Systems

How a Bidirectional Knife Gate Valve Enhances Fluid Control Systems

Understanding the Bidirectional Knife Gate Valve

Definition and Functionality

The bidirectional knife gate valve is a type of valve specifically created to regulate fluid flow in two directions efficiently and effectively, unlike conventional valves that only allow flow in one direction. Bidirectional knife gate valves can facilitate fluid movement from either side, making them adaptable for different industrial uses, especially when changes in flow direction are common.

Key Components

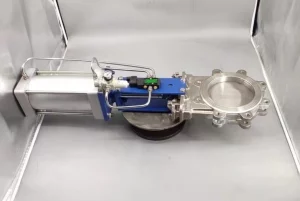

A bidirectional knife gate valve typically consists of parts like the valve body, gate, seat rings, and an actuation mechanism. The valve body is commonly crafted from materials such as carbon steel or stainless steel to endure challenging environments. The gate, usually fashioned from stainless steel varieties like AISION 304 or AISION 316, slides into position to control the flow of fluids. Seat rings, often composed of CF8M steel, are used to create a secure seal and avoid leaks. The way the system is activated can be done manually or automatically to provide versatility in its operation.

Differences Between Unidirectional and Bidirectional Knife Gate Valves

Unilateral knife gate valves are crafted to regulate the flow of liquid in one direction, whereas bidirectional valves can oversee flow from two directions as needed in systems where fluid direction reversals are necessary without altering the valve configuration setup itself for optimal functionality and versatility in diverse applications due to their advanced dual sealing features.

Advantages of Using a Bidirectional Knife Gate Valve in Fluid Control

Improved Flow Control Capabilities

Knife gate valves that can control flow in both directions offer improved management of fluid movement in various industries such as mining and wastewater treatment where frequent adjustments in flow direction are necessary. The MGA/MGD model knife gate valves, with flange/wafer/lug designs, cater to a range of industrial needs and are well-suited for challenging environments.

Enhanced Durability and Longevity

These valves are designed to withstand conditions because they are made of durable materials, such as carbon steel and stainless steel, that ensure their longevity even with high-speed flows and particulate media without experiencing much wear and tear over time. A key feature that prolongs the lifespan of these valves.

Versatility Across Various Applications

Bidirectional knife gate valves are utilized in industries for their versatility and adaptability to different applications such as mining operations and power generation facilities as well as chemical plants and wastewater treatment facilities among others. They play a role in handling abrasive slurries in these sectors. The widespread use of the MDT Double gate knife gate valve in the Pulp and Paper industry showcases its versatility and applicability, in this field.

Technical Aspects of Bidirectional Knife Gate Valves

Material Selection and Its Impact on Performance

The selection of materials plays a role in determining how well bidirectional knife gate valves perform and last over time. Chosen materials consist of carbon steel for its strength and affordability as well as stainless steel, for its ability to resist corrosion. For example, the designation Body Carbon Steel / AISII316 signifies the various choices accessible depending on the requirements of a given application.

Design Features That Enhance Efficiency

Sealing Mechanisms

Reliable sealing methods play a role in avoiding leaks and maintaining smooth operations of systems or equipment. Bidirectional knife gate valves commonly come with seated configurations to enable shutoff in both directions effectively. Thanks to the seated setup, these valves, can prevent leaks efficiently even when operating under high-pressure conditions.

Actuation Methods

Different ways to operate valves range from hand-operated handwheels to automated systems that use electric actuators, providing accurate control based on system needs and requirements for valve operation precision, with automation options offering added functionalities such as limit switches and positioners to improve efficiency during operations.

The thorough grasp of knife gate valves highlights their significance in today’s fluid control systems in different industries. Their construction and material choices alongside their adaptable uses establish them as vital elements, in effectively overseeing intricate fluid dynamics.

Applications of Bidirectional Knife Gate Valves in Industry

Common Industries Utilizing Knife Gate Valves

Mining and Mineral Processing

In the mining and mineral processing sector, bidirectional knife gate valves play a role in managing abrasive slurries. Their sturdy construction and capacity to offer directional sealing make them highly suitable for this challenging setting. The MGA/MGD model knife gate valves come in flange/wafer/lug designs tailored for industrial uses, especially well suited for handling such abrasive substances.

Wastewater Treatment

The wastewater treatment industry greatly benefits from utilizing knife gate valves because of their dependable sealing abilities and capacity to manage suspended solids effectively. These valves guarantee smooth flow regulation and prevent blockages—an essential aspect in treating wastewater with diverse compositions.

Pulp and Paper Industry

In the pulp and paper industry, these valves are indispensable for managing high-concentration or contaminated media. The MDT Double gate knife gate valve is a double gate valve widely used in the Pulp and Paper industry, showcasing its effectiveness in handling challenging materials like recycled fibers.

Specific Use Cases within Each Industry

In mining operations, bidirectional knife gate valves are commonly used to manage the flow of slurry in ore extraction processes. They play a role in wastewater treatment facilities, where they oversee the intake and release of water, ensuring effective management of contaminants. Moreover, these valves are essential in the pulp and paper sector as they help in transporting pulp mixtures across different production stages to uphold operational efficiency.

Choosing the Right Bidirectional Knife Gate Valve for Your Needs

Factors to Consider When Selecting a Valve

Pressure and Temperature Ratings

Choosing the bidirectional knife gate valve involves taking into account the pressure and temperature specifications to meet the needs of the system effectively, such as DN 50 to DN 400 with a working pressure of 10 bar for specific uses and higher pressures for different applications.

Size and Compatibility with Existing Systems

The valve dimensions need to match the specifications of the system, for smooth integration purposes, providing flexibility in selection from sizes ranging between DN 50 and DN 900 (larger upon request), catering effectively towards operational requirements.

Maintenance Considerations for Optimal Performance

Keeping bidirectional knife gate valves running smoothly requires upkeep to ensure they perform at their best capacity. This involves inspecting seals for signs of wear and tear, making sure that actuation mechanisms operate properly, and swapping out any worn-out parts when necessary. The design includes a packing system, with conveniently accessible and adjustable packing glands to guarantee a secure seal, making maintenance tasks easier to handle.

Miwival Products and Applications

Miwival valve products are designed for various industrial uses. They have innovative features like machined cast or fabricated two-part bolted bodies with HMWPE liners to improve performance by smoothly guiding the gates during operation. These valves come with automated features and gate guards that meet EU Safety Standards to enhance safety and functionality in industries.