How Do Safety Valves Ensure Safety?

Understanding Safety Valves

Safety valves play a role in different industrial setups by overseeing the safe and effective functioning of equipment through the management of pressure levels in a controlled manner. These valves are specifically created to manage pressure consistently despite changes in upstream pressure or flow requirements. Their main purpose is to lower a high pressure to a lower level at the outlet to safeguard delicate machinery and maintain operational stability.

Functionality of Safety Valves

The core function of the safety valve is to automatically open and discharge the medium when the system pressure exceeds the specified value to reduce the pressure and prevent accidents in equipment or pipelines due to overpressure.

Under normal working pressure, the valve disc of the safety valve is pressed tightly against the valve seat by the force of a spring or a heavy hammer, etc., and remains closed to prevent medium leakage.

When the system pressure exceeds the set value (i.e. the opening pressure of the safety valve), the force of the medium on the valve disc is greater than the force of the loading mechanism, the valve disc begins to separate from the valve seat, the safety valve opens, and the medium is discharged through the valve seat.

As the medium is discharged, the system pressure gradually decreases. When the pressure drops to the normal working range, the force of the loading mechanism is greater than the force of the medium on the valve disc again, the valve disc presses the valve seat again, the safety valve closes, and the medium discharge stops.

Difference Between Safety Valves and Other Valves

Safety valves, like check valves, are automatic valves. They do not require actuators and can be opened and closed by the pressure of the medium itself. Other valves such as ball valves, butterfly valves, gate valves, etc. require external manpower or other energy to operate.

Therefore, safety valves have the characteristics of light and compact structure, easy installation and cost saving. There are many types of safety valves, especially spring-type safety valves, which have light and compact structures, unrestricted installation positions, and are suitable for various working conditions. In addition, the structure of the safety valve is relatively simple, so the installation and adjustment are easier, suitable for various pressure vessels and equipment. Compared with other valves, the automaticity of the safety valve can save the cost of assembling the actuator.

Role of Safety Valves in Safety

Safety valves play a critical role in ensuring safety within systems to avoid overpressure buildup that would result in equipment malfunction or damaging incidents. Safety valves serve as a safety measure by automatically relieving pressure when it reaches a set level. This safeguards equipment and individuals from damage and danger.

Importance of Safety Valves in Systems

Safety valves assist in safeguarding systems against possible overpressure situations using the implementation of a necessary safety mechanism against the same.These safety mechanisms preserve systems from possible failure due to uncontrolled increases in pressure.All these valves work to discharge any energy present within a system in controlled manners so as to prevent any resulting harm or injury.

Valves are used in industries like oil and gas exploration and production and chemical plants and power plants where high pressure is prevalent. They work by responding to increasing pressures to facilitate the smooth operation of systems and adherence to safety standards.

Integration of Safety Valves with Pilot Operated Systems

Incorporating safety valves into pilot operated systems boosts safety by blending control with dependable overpressure safeguarding measures.In these setups, the safety valve manages operating pressures while the relief valve remains prepared to step in if pressures surpass safe thresholds.

Incorporating this setup guarantees that in case of a malfunction or sudden power surge in the system occurs unexpectedly there’s a safe system ready to avert any harm or danger effectively at all times. The collaboration between these two valve variants offers a encompassed safety net by catering to the regular operational requirements as well as handling unforeseen emergencies simultaneously.

In short know how safety valves work together with pressure relief valves underscores their role in maintaining safety in different industrial settings. Their capacity to regulate pressures effectively and provide protection against excessive pressure situations makes them vital elements in contemporary engineering setups.

Advantages of Using Safety Valves for Safety

Reliability and Precision in Operation

Safety valves are well known for their performance and accuracy in managing pressure within systems effectively. They are designed to adjust pressure levels to guarantee a steady and reliable flow for downstream systems. This reliability is especially vital in environments where even slight pressure variations can cause major operational problems or damage equipment. The two-stage structure of these valves.

In fields like pharmaceuticals and petrochemicals where precise pressure control is crucial for safe and efficient operations safety valves play a significant role by maintaining specific pressure levels consistently This ensures the smooth functioning of processes and reduces the risk of safety hazards or quality issues in industries such as food processing.

Versatility Across Different Applications

The adaptability of safety valves allows them to be used in a variety of applications in industries with ease. Their capability to manage fluid types such as gases and liquids along with their effectiveness in diverse temperature and pressure ranges expands their usefulness. Whether deployed in steam systems water distribution setups or gas pipelines these valves deliver performance tailored to meet the unique requirements of each scenario.

Furthermore, the flexibility of safety valves enables integration into current systems. Their construction is adaptable to setups and dimensions making them a suitable option for both new construction and renovation endeavors. This flexibility not only expands their range of applications but also aids in cost efficiency by minimizing the requirement for multiple valve types within a singular system.

Introduction of Miwival and Its Products

Miwival: Professional Valve Company

One of the companies in the industry is Miwival, known for producing premium valve solutions and innovative technologies tailored to meet a wide range of client needs due to its years of experience and commitment to excellence in providing valve products for different industrial uses.

The knowledge of Miwival goes beyond manufacturing. It encompasses research and development focused on advancing valve technology. Through staying up to date with industry trends and integrating state of the art innovations into their products, Miwival guarantees that its offerings provide top notch performance and dependability.

4 Reasons to Buy Miwival’s Valve Products

- Quality Control at Miwival is a priority with a focus on ensuring that every valve goes through thorough testing to meet strict industry benchmarks for performance and longevity assuring customers of reliable results even in challenging environments.

- At Miwival,the focus is on innovative design emphasizing both creativity and practicality in their approach to creating valve solutions that are not only high-tech but also easy to use and efficient for customers’ needs.

- Miwival offers a range of support services to help customers with their valve products at every stage of the process. From installation tips to maintenance advice and beyond! Their team of experts is always on hand to provide assistance and guidance whenever you need it.

- Miwival provides customization options for its valve products to meet the needs of each application. Clients can request features or modifications to ensure that the valves are compatible with their systems and operations.

When customers opt for Miwival’s valve products they not get access to high quality equipment but also benefit from a wealth of knowledge and assistance that enriches their experience with industrial valve solutions.

FAQ

Q: What are the basic parameters of safety valves?

A: It is necessary to confirm the safety valve’s nominal pressure, working pressure rate, discharge pressure rate, diameter, and material, etc.

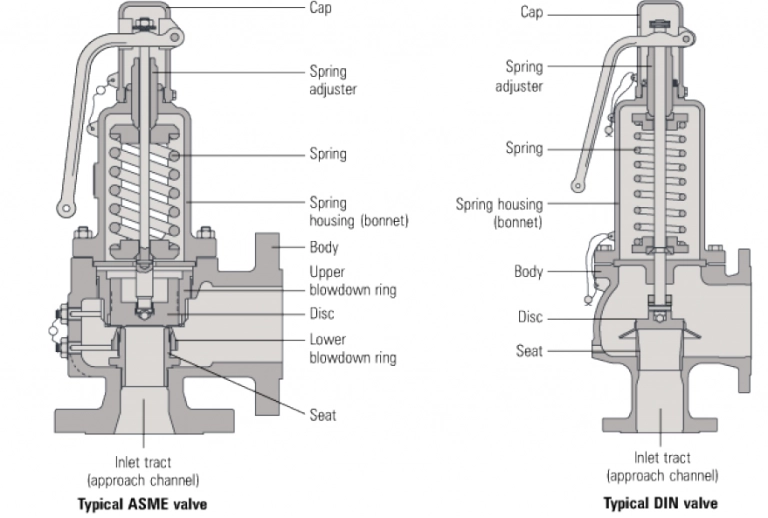

Q: What are the types of safety valves according to their structure?

A: Safety valves can be divided into three types according to their overall structure and loading mechanism: heavy hammer lever type, spring type and pulse type. The most commonly used is the spring type safety valve.

① The heavy hammer lever type safety valve uses a heavy hammer and a lever to balance the force acting on the valve disc. It can use a heavy hammer with a smaller mass to obtain a larger force through the increasing effect of the lever, and adjust the opening pressure of the safety valve by moving the position of the heavy hammer (or changing the mass of the heavy hammer).

② The spring type safety valve uses the force of the compression spring to balance the force acting on the valve disc.The compression amount of the spiral coil spring can be adjusted by turning the adjusting nut on it.

③ The pulse type safety valve consists of a main valve and an auxiliary valve. The main valve is operated by the pulse action of the auxiliary valve. Its structure is complex and is usually only suitable for boilers and pressure vessels with large safety discharge volumes.