Key Advantages of Butterfly Valve Systems in Modern Engineering

Understanding Butterfly Valve Systems

Overview of Butterfly Valves

A butterfly valve is a kind of valve design that involves a body and a disk closure member that can rotate 90° to open and close the valve when supported by its stem pivotally. Its design provides versatility and efficiency for uses with high recovery rates. There are types of butterfly valves available such, as lined and eccentric valves.

Basic Components and Functionality

The butterfly valve comprises three parts: the valve body, the valve disc, and the shaft. That work together to make it more compact than other valve types. Operating the valve disc by rotating it using a rod or handle allows for opening and closing actions. Its shape, round or oval, is designed to minimize flow resistance when the valve is open.

Main Advantages of Butterfly Valves

Compact Design and Space Efficiency

Butterfly valves offer a design as one of their main benefits in terms of weight and space reduction. Triple Offset Butterfly Valves can decrease both weight and space requirements, which facilitates easier installation due to their lighter weight and reduced need for pipe bracing. This characteristic proves especially advantageous in industries facing space limitations.

Cost-Effectiveness and Economic Benefits

Butterfly valves are recognized for being budget-friendly due to their design which leads to reduced production expenses when compared to intricate valve models such as gate or globe valves. The incorporation of an off-center disc, exclusive seat design, RPTFE sealing technology, and other attributes contribute to making high-performance butterfly valves an efficient and durable option that is both lightweight and cost-effective while ensuring a tight seal, for an extended period.

Ease of Installation and Maintenance

Butterfly valves are designed to be simple and easy to install and maintain due to their structure. They are typically smaller in size compared to valves, which makes them suitable for use in tight spaces without the need for major adjustments or extra support structures. Their opening and closing system also streamlines operational processes.

High-Performance Butterfly Valves in Modern Applications

Enhanced Durability and Reliability

Butterfly valves designed for performance are built to last and deliver reliable operation in tough conditions. Series is crafted to offer a tight seal in both directions and separate the line’s contents from the stem or valve body for efficient functioning, under high pressure or velocity situations.

Versatility Across Industries

Butterfly valves are commonly used in a range of industries because they can easily meet various operational needs.

Oil and Gas Industry Applications

Butterfly valves are essential in the oil and gas industry for their effectiveness in conditions. Triple Offset Butterfly Valves stand out for their benefits over other valves commonly found in upstream operations. Their consistent performance in extreme temperatures makes them ideal for important processes.

Water Treatment Systems Usage

Butterfly valves are commonly used in water treatment systems for their sealing properties, making them a popular choice for water pipe applications as they offer ease of installation and effective flow control due to their lightweight design.

In summary, the key benefits of a butterfly valve are its compact design, cost efficiency, user-friendliness, durability, and adaptability to industries. These characteristics establish them as a crucial element in contemporary engineering setups where effectiveness and dependability are crucial.

Technological Advancements in Butterfly Valve Design

Innovations in Material Science

Innovations in material science have greatly improved the effectiveness and durability of butterfly valves in times with the utilization of advanced elastomers such as BUNA N Food Grade✵ and EPDM Food Grade✵, enhancing the sealing performance of resilient seated butterfly valves for higher speed applications while offering superior durability against wear and tear to extend their lifespan. Furthermore, using steel and nylon-coated disc materials improves the valves’ strength and resistance to corrosion, enabling them to work effectively in challenging conditions.

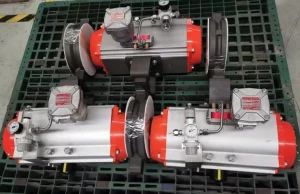

Integration with Automation Technologies

The combination of automation technologies with butterfly valves has completely transformed how they work nowadays. Current butterfly valves come with capabilities that make it simple to automate them using electric systems for switching functions or adjusting applications. The ISO 5211 top flange layout accommodates this automation feature, allowing for the management of fluid flow with little need for human involvement. This progress not only enhances operational effectiveness, it also lowers the chance of human errors and guarantees a steady performance in different industrial environments.

Environmental Impact and Sustainability

Energy Efficiency Considerations

Butterfly valves play a role in saving energy by reducing resistance to fluid flow and minimizing pressure loss when the valve is in use. The efficient design of these valves enables fluids to pass through smoothly without requiring excessive energy for pumping tasks. This feature is especially advantageous for industries operating on a scale where managing energy consumption is a top priority. Improving the flow dynamics in systems, with butterfly valves installed, helps industries save amounts of energy while ensuring precise process control.

Reduction in Carbon Footprint

The small and lightweight nature of butterfly valves is crucial in helping industrial operations reduce their carbon footprint effectively. Due to their design and petite size as opposed to larger valve varieties like gate or globe valves, butterfly valves need less material for production, resulting in decreased emissions during manufacturing processes. Additionally, their simple installation and maintenance requirements mean fewer infrastructure changes are necessary, thus minimizing the impact further.

Miwival: Excellent Butterfly Valve Solutions

Miwival is known for offering exceptional butterfly valve solutions designed to cater to a wide range of industrial requirements. Miwival products with care and integrate state-of-the-art technologies to guarantee dependability and effectiveness in various uses.

Miwival high performance butterfly valves use off center disc designs and exclusive seat technologies to provide effective sealing solutions that are durable and budget friendly compared to conventional gate valves, making them a great choice for industries looking for reliable yet affordable valve options.

Miwival consistently raises the bar in the industry for excellence in quality and performance while prioritizing responsibility through the integration of advanced technology with sustainable practices.