When most pulp and paper companies take samples to test the slurry concentration, they firstly collect pulp samples manually in the pulp tank or stabilizing box; secondly, they install ordinary ball valves on the pulp conveying pipes to collect the materials. The slurry used for papermaking is a mixture of liquid and solid. Slurry samples are collected manually from pulp tanks or stabilizing boxes. Since operators collect slurry samples in different ways and are very random, it is very easy for the collected slurry samples to be inconsistent with the actual slurry concentration reflection value. If an ordinary ball valve is installed on the slurry pipe to discharge and collect the material, part of the moisture in the slurry will be blocked, so that the collected slurry sample cannot truly reflect the actual slurry concentration. The welded slurry pipe is often blocked by dried slurry.

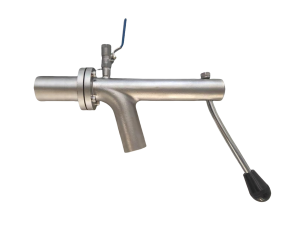

Miwival manual slurry sampling valve completely solves the collection error of slurry samples during the sampling process. It’s inserted into the slurry pipe to directly collect the flowing slurry. It can repeatedly enter a fixed position for each collection and accurately collect the actual concentration of slurry.

Miwival manual slurry sampling valve is used in papermaking workshops that produce thin paper, writing paper, cultural paper, copy paper, and coated paper.